AS LUBRICATIVE AS WE DO

润滑尽我所能

- Industrial Capacity

- Technological Leadership

- Quality Excellence

- Innovation Pioneering

-

Countries/Markets Served40+

-

Global Clients Supported3000+

-

Complete Equipment Systems200+

-

Industry Experts & R&D Specialists50+

-

R&D Centers3

Lubricant Additives Research Institute

Analysis & Evaluation Center

Pilot Testing Platform

Pursuit of Excellence

China Engine Innovation Alliance Council Member Co-developer of China Diesel D1/Gasoline G1 standards

China CP3 Alliance Member Contributor to low-speed pre-ignition test bench standards

Industry-Leading Formulation Expertise

One of China's most comprehensive lubricant additive portfolios

Full-Spectrum Applications:

-

Application Areas of Single Additives

Application Areas of Single Additives-

Lubricant Additive Compounding

-

Lubricant Blending

-

-

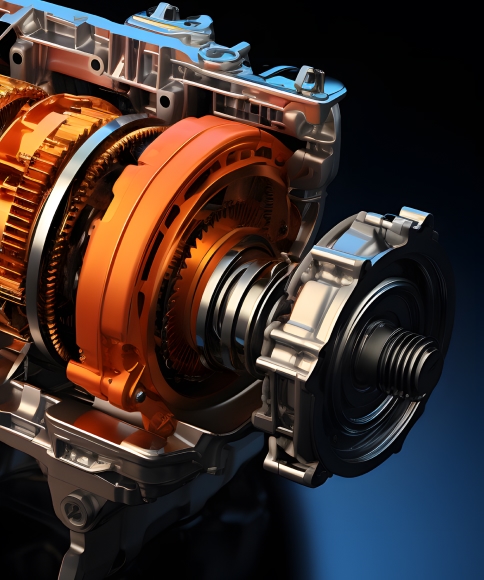

Automotive

Automotive-

Engine oils

-

Transmission fluids

-

-

Industrial Manufacturing

Industrial Manufacturing-

Hydraulic fluids

-

Gear oils

-

Specialty lubricants

-

-

Off-Road Equipment

Off-Road Equipment-

Construction machinery oils

-

Agricultural oils

-

-

Marine Transportation

Marine Transportation-

Marine engine oils

-

Quality as Our Foundation

Compliant with ISO 9001 Requirements Implementing risk-based thinking and process approach for full-process quality control, with emphasis on procedural management

-

R&D Management

Industry leadership

Benchmark standards

Stage-gate reviews -

Supply Chain

Supplier development audits

Performance evaluations

KPI monitoring -

Production Control

Raw material inspection system

In-process control system

Final release verification -

Application Support

Rapid response

Technical expertise

Application performance reviews

New Energy Solutions

Breaking through technical bottlenecks to secure supply chain independence

-

Methanol

Methanol -

Next-Gen Biofuels

Next-Gen Biofuels -

Liquid Ammonia

Liquid Ammonia -

Hydrogen

Hydrogen

Wind Turbine Lubricants

Pioneering Green Power – The New Benchmark in Wind Energy Lubrication

Bio-Based Phenate Detergents

Sustainable Alternative to Traditional Sulfurized Alkylphenates

-

Regulatory Compliance Alternative

-

Bio-Based Material

-

Performance Parity

-

Regulatory Compliance Alternative

To address EU restrictions on TPP, we have developed hydrogenated cardanol as a dodecylphenol replacement.

-

Bio-Based Material

Derivatives of Cashew Nut Shell Liquid (CNSL) have found applications in numerous industries in recent years. Its primary component is anacardic acid. After decarboxylation, cardanol is obtained, followed by hydrogenation to remove unsaturated bonds, yielding hydrogenated cardanol. As a bio-based raw material, it is widely available and holds a price advantage over dodecylphenol.

-

Performance Parity

Calcium sulfonated alkylphenates synthesized from hydrogenated cardanol demonstrate comparable: ·Physicochemical properties ·Simulated test results to conventional calcium sulfonated alkylphenates."